The Application Case

A. The instrument parameters

Instrument model: the Accura III 4030 ITO increases and size and defect measuring instrument measuring stroke (mm) : 400 * 300 * 200 pairs of camera system: the main color CCD camera system carry 520 TV line, auxiliary megapixels camera aboard camera system.

Double optical system: with continuous variable are the main lens, auxiliary 20 x metallographic microscope lens with high performance.

Measuring software: EF8000 proprietary software

Magnification: main optical system about 26-222 times (optical ratio of 0.7 to 6 times), auxiliary optical system about 260-260 times (optical ratio is about 0.7 to 5 times).

B. The workpiece measurement requirements

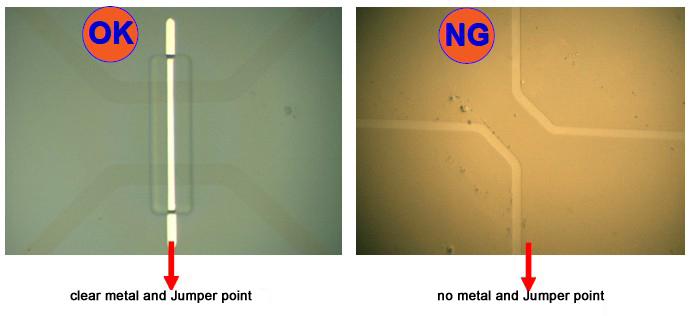

1. Examine the crushing effect of the thermal conductive particles status and quantity.

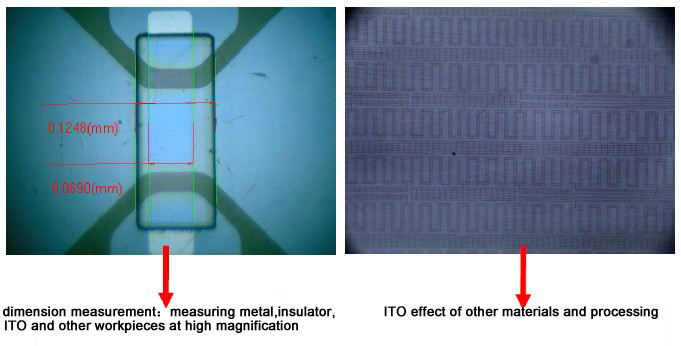

2. Inspect ITO lines and size measurement.

3. The glass joint after foreign body check.

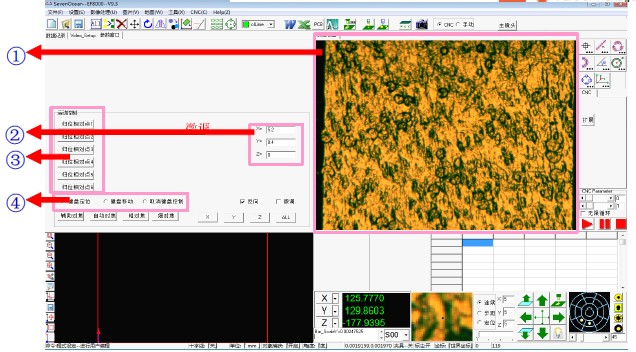

C. Professional operating software

Humanized operate software:

(1) real-time show software in place; (2) the user can set mobile distance; 3. User can expect six group examines trajectory; (4) through the keyboard direction key move and positioning.

D. Review practices

1. The workpiece is fixed on the workbench fixture (jig has been fixed in advance).

2. To adjust to the appropriate optical lens optical ratio;

3. With the main lens first find detection target location (as shown on the right position, for example);

4. Then switch directly to the high rate of lens in the software, you can find the location of the need to detect;

5. The conductive particles, ITO, foreign bodies, such as analysis of test results;

6. Test report save picture.

E. Examine the effect and the result analysis

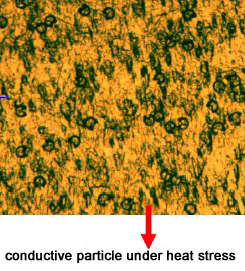

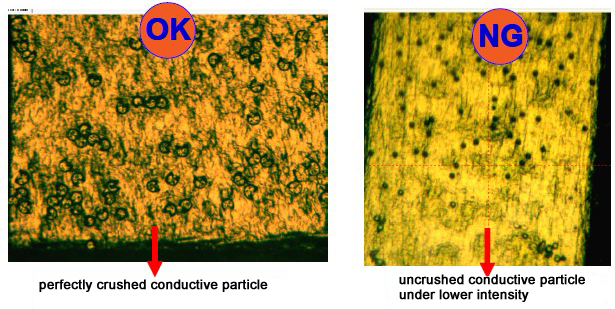

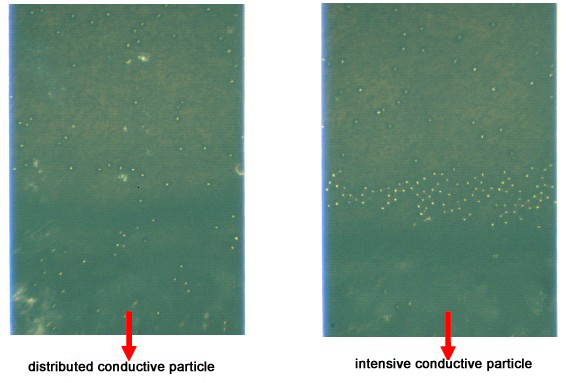

1. Review of conductive particle effects:

Adjust the ratio to about 300 times to 600 times. ITO and FPC/TAB foot overlap the effective number of conductive particles must be greater than or equal to 10 PCS, less than 10 PCS for not qualified.

2. ITO examines effect (as shown in the figure below) :

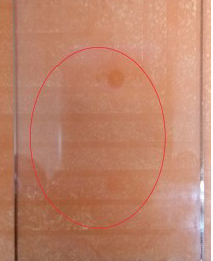

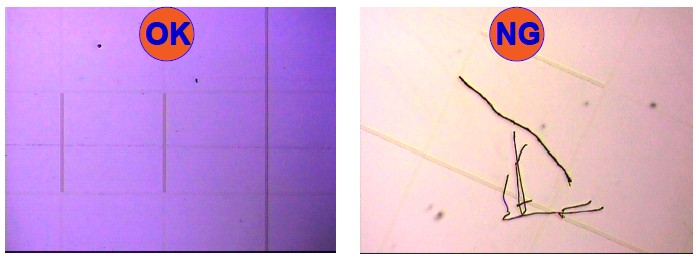

3.Glass foreign bodies to examine effect:

When the Lens (cover), OCA glue, ITO glass laminating, between directly by optical amplifier on the measuring software review product whether there is any foreign body; As shown in the above: left for joint after the product is OK, right for joint after the product is NG.

F. Model measure Suggestions and recommendations

This machine is used for the demonstration equipment, customers can according to the appearance of the product size, select AccuraIII 3020/4030/5040 models.

Artifacts in viewing or measurement, can advance the workbench tops a fixture, then default good review trajectory in the EF professional software, the operator can quickly find the target location.

Corporate Awards

Corporate Awards Enterprise Culture

Enterprise Culture Demo Centre

Demo Centre Promotional Video

Promotional Video Talent Strategy

Talent Strategy Company Profile

Company Profile Contact Us

Contact Us

Shenzhen

Shenzhen Korea

Korea Taiwan

Taiwan Nanjing

Nanjing Shanghai

Shanghai Suzhou

Suzhou Chengdu

Chengdu